There are a number of technologies that are used today to split water-miscible cutting fluids, although the water phase with water-soluble substances often remains a problem. Standardisation of the splitting process is therefore sensible and necessary, as the water phase (main part) should be reusable after treatment, but at least purified in such a way that it can be discharged a.) into the sewage system or b.) into a biological sewage treatment plant.

However, this discharge requires compliance with certain limit values, as the degree of contamination when discharged into the sewage treatment plant is subject to a significant surcharge. However, reuse actually requires drinking water quality.

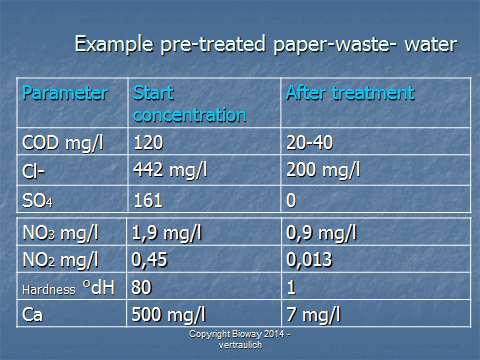

The new method presented here is able to achieve a COD of less than 500 mg/l using an AOP (advanced oxidation process) method. Only the salt load / conductivity must be reduced in some cases if reuse is to take place. However, this is easily possible as the water phase is clear, colourless, particle-free, with a reduced COD value and is simply rinsed via an ion exchanger.

The process is a standard that can treat up to 90% of all cooling lubricants available on the market. It is also worth noting that water-miscible cooling lubricants can have a starting COD of 70,000 to 160,000 mg/l. A COD reduction to less than 500 mg/l is ‘outstanding’!

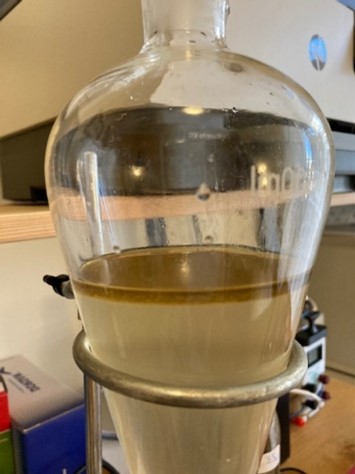

However, no one would seriously consider this technology unless the handling is relatively simple, the operating costs are low and the investment in a system is acceptably low. For example, the price for cleaning one (1) cubic metre of coolant is less than €10. The splitting of the emulsion is energy-free and no demulsifies is used, as all added substances have to be removed from the water again.

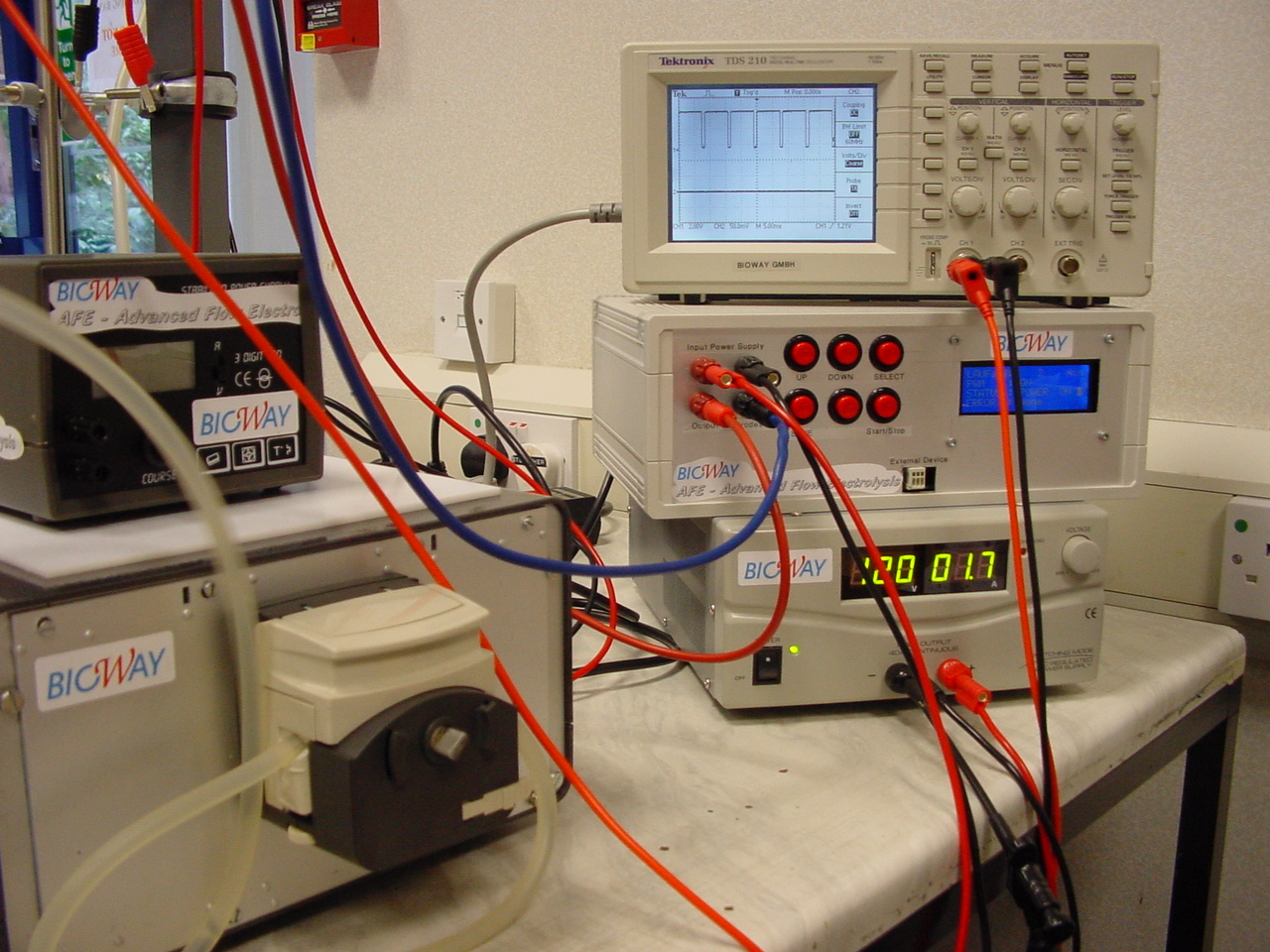

and wihout depot effects. The Advanced-Flow-Electrolysis is the distinct answer for all these problems and could handle up to a few hundred m³ per hour. Also this technology is the right answer for micro-pollutants for elimination out of municipal waste water instead using ozone and / or powdered activated carbon.

and wihout depot effects. The Advanced-Flow-Electrolysis is the distinct answer for all these problems and could handle up to a few hundred m³ per hour. Also this technology is the right answer for micro-pollutants for elimination out of municipal waste water instead using ozone and / or powdered activated carbon.